DAI Video Intelligence Built for Manufacturing

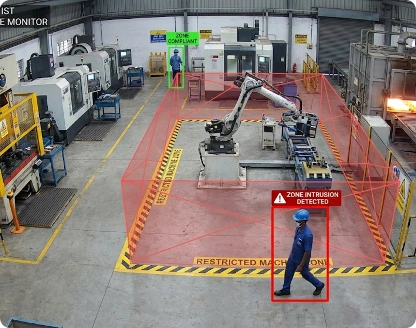

Mikshi AI turns existing factory CCTV cameras into a real-time intelligence system that monitors safety, security, and operational activity across manufacturing environments.

With support for multiple use cases—such as PPE compliance, restricted zone monitoring, workforce presence, vehicle movement, and incident investigation—the platform delivers actionable insights from a single, unified solution.

Mikshi AI integrates easily with your current camera infrastructure and supports on-premise, cloud, or hybrid deployment, enabling quick installation without disrupting production. New use cases can be activated as requirements evolve, without changing hardware.